Valve driver - worth knowing about the queen

Highnesses require special attention and patience

Intensive Individualanpassug

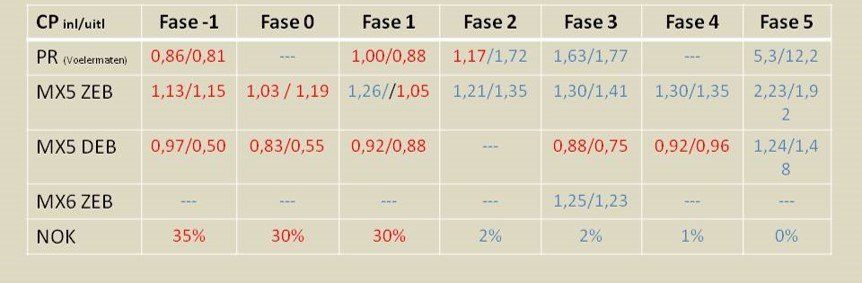

Manual adjustment of valves does not meet the tolerances required by the design. Because of the indirect gauge process for adjusting the valves, preliminary work is required to determine if the motor and its components are suitable for this procedure. For this purpose, the following project steps must be followed: Determination and quantification of mechanical component tolerances of the engine components and determination of the resulting basic tolerances. The mechanical tolerances of the engine components involved are of the same order of magnitude as the permissible setting tolerances. Examination of the adjustment options, in particular the behavior of valve springs with an analysis system.Development of a valve clearance measuring system with evaluation of the measuring equipment capability.Reference measurements on manually set valves of different workers.Measurement at different KW and NW positions. Turning after setting and remeasuring.Revaluation of the results Decide if a motor is suitable for the process at all.Fixing of technically possible Cp and Cpk values These definitely depend on the size of the motors and the quality of the components on the motor. Selection of a system variant and thus a degree of automation as a function of the necessary Taktzeit.A hand, our experience can be said that for commissioning and verification phase with a lot of patience must be worked. It works quite quickly, the Einstellergebnisse be better than by hand adjusted valves. For further optimization, see also the following slide, it can take quite a few months. As an example, here we show you a project course: The result overview shows 5 different phases, which have been distributed over one year, until 4 engine types were integrated. A meaningful population of measurements is always needed for meaningful actions before making any changes. As a common goal, we set a Cp value of 1.2 and a Cpk value of 1.0. The NIO rate should be less than 2%. Phase -1 were manual settings during the analysis phase. 0 and 1 were the first tests with a test system. Phase 2 was the start with the fully automatic setting. Until phase 5, it took another 6 months until There are enough readings available for a statistical evaluation. You see queens are special!