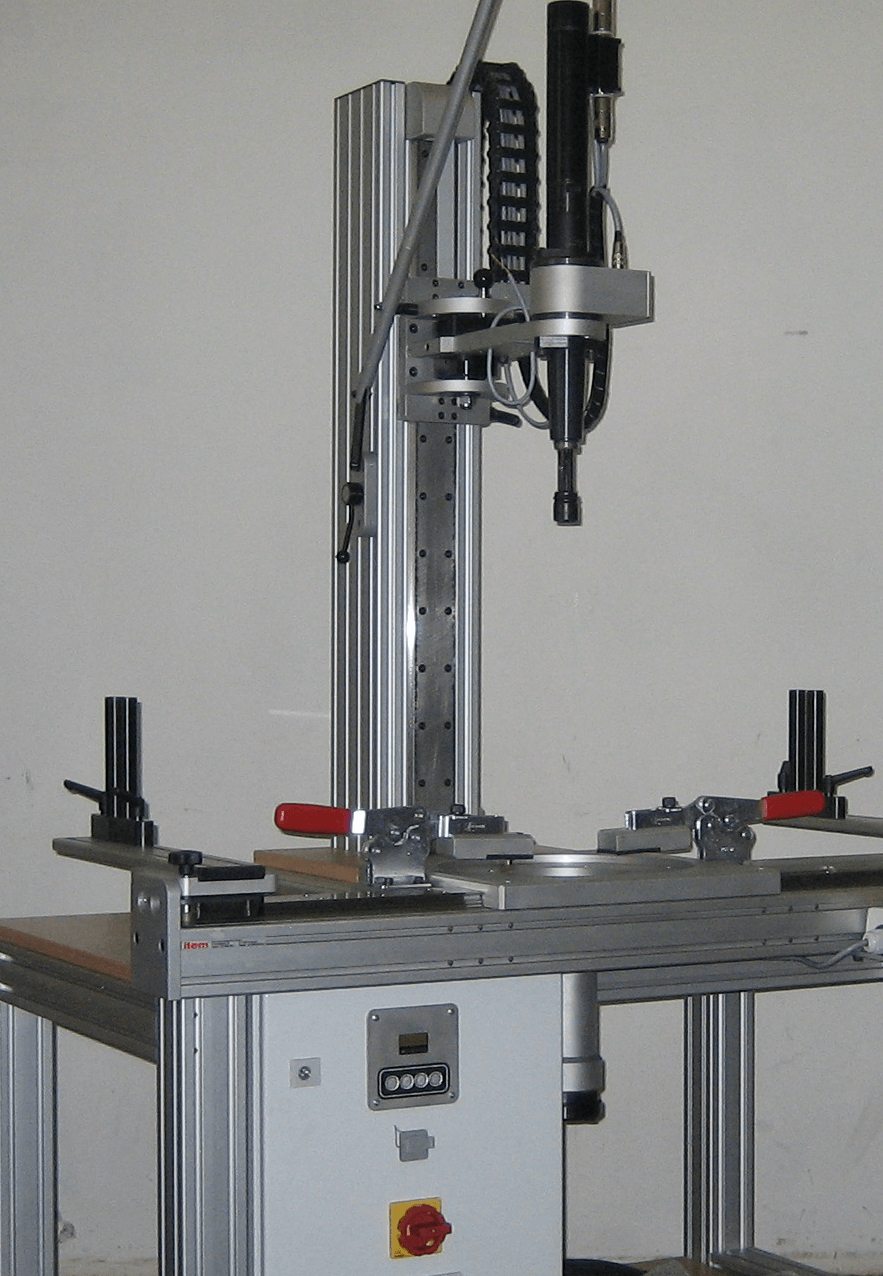

screwdriver test

Testing Technology

Therefore, examine whoever binds forever

ensured

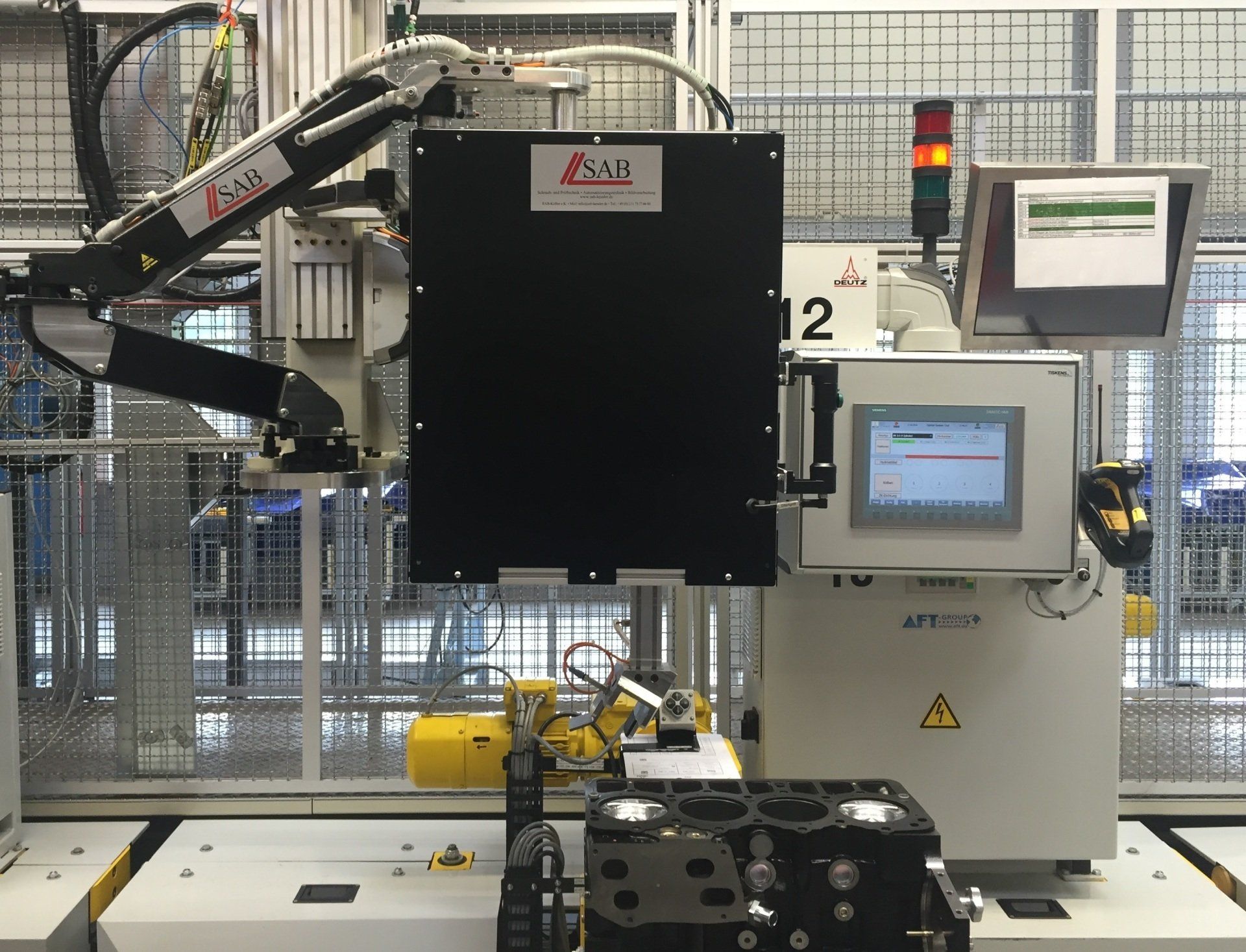

There are a variety of reasons for testing systems. You want to make sure that a Class A gland is actually one. Or is it indispensable for you that your systems are always optimally calibrated? Among our test systems you will also find multi-channel measuring devices and rework stations, if the test was previously NIO. Here are some examples.

Technical data: Simulation of bolted jointsChecking of torque wrenches2 Measuring circuits per simulator, which monitor each otherMultisk disc brakes reduce possible "stick slip effects" Maximum torques: 30 Nm / 80 Nm / 130 Nm / 270 Nm

Specifications: This system can test 3 window fittings at once. It will run for 30,000 cycles while monitoring the actuation torques. The test must be performed with a constant force in both directions. This was realized by pneumatic cylinders with a corresponding wiring. Test bench mechanics with 3-EC motor drives and torque angle sensors. PC evaluation system with special software and visualization of the test procedure.

Technical specifications:

Technical specifications:

Technical specifications:

Technical data: Checking the closing forces for the glove box flapsThe glove compartment flap picking armTrain sensor and electronic data loggingMeasuring deviceRoll case for transportMaximum closing forces: 150 N

Technical data: The adjustment wheel of the ventilation flap is operated by means of a friction-wheel drive System can be used with 12 V in ACCU operation and 230 V Torque-rotation angle sensor for measured value acquisition Maximum actuating forces: 5 Nm

Technical data: Adjustable coupling frame for different flap versionsAluminium frame with vacuum cups adjustableFeather scale with tension sensor and electronic data loggingCurrent measuring meterDisplacement, Rolling suitcase for transportMaximum closing forces: 200 N